openers

The next generation design of the C2 Contour IP Opener System (patent pending) improves opener wear and durability.

INJECTED POLYMER OPENER SYSTEM

Wear Life

32% increase in the tungsten carbide applied to the highest wear regions of the opener.

Improved Soil Flow

The low friction properties and narrow profile of the polymer boot minimizes the opener width travelling through the soil.

Reduced Opener Length

Smaller surface area for soil build-up and reduce force requirements for penetration.

Reduced Build-Up Inside

The polymer boot reduces build-up of fertilizer and seed treatment dust inside openers in high humidity weather.

No Hose Clamps

A special hose holder is used with the polymer boots to secure secondary hoses.

Granular, Liquid, or Gas

Polymer boot is designed to apply all three forms of fertilizer.

Paired Row Double-Shoot

The patented paired row double-shoot opener places two distinct rows of seeds 4 inches apart with fertilizer placed centrally and 3/4 inches below the seed rows. The 12 inch shank spacing, paired row opener combination provides an 8 inch seed row spacing. Narrow row spacing closes the crop canopy more rapidly setting the stage for improved sunlight capture, water use efficiency and crop competition. Angled carbide faces on the opener minimizes soil fracturing for excellent seed bed consistency and outstanding seed to fertilizer separation. Available only on 12 inch spacing.

Side Band Double-Shoot

This opener places a distinct seed row 2 inches to the side of the knife followed by a fertilizer band, which is placed directly behind the knife and ¾ inch below the seedbed. This patented design results in outstanding fertilizer separation and improved seedbed consistency by minimizing soil fracturing.

CAST OPENER SYSTEM

Narrow Knife Single-Shoot

This opener places a narrow ½ inch ribbon of seed in each seed row. This opener cuts a smooth narrow channel for seed placement and has the lowest soil disturbance of the openers available on the C2 Contour. This opener has proven to be popular for sticky soils having high clay content.

Side Band Double-Shoot

This opener places a distinct seed row 2 inches to the side of the knife followed by a fertilizer band, which is placed directly behind the knife and ¾ inch below the seedbed. This patented design results in outstanding fertilizer separation and improved seedbed consistency by minimizing soil fracturing.

Spread Tip Single-Shoot

This opener places a 3 inch wide ribbon of seed in each seed row. The opener cuts a smooth, level seed bed that results in consistent seed placement designed to minimize soil disturbance. The spread tip opener, with its high seed bed utilization, is an excellent choice for applying low to moderate fertilizer rates with seed.

Paired Row Double-Shoot

The patented paired row double-shoot opener places two distinct rows of seeds 4 inches apart with fertilizer placed centrally and 3/4 inches below the seed rows. The 12 inch shank spacing, paired row opener combination provides an 8 inch seed row spacing. Narrow row spacing closes the crop canopy more rapidly setting the stage for improved sunlight capture, water use efficiency and crop competition. Angled carbide faces on the opener minimizes soil fracturing for excellent seed bed consistency and outstanding seed to fertilizer separation. Available only on 12 inch spacing.

Mudguards

Mudguards reduce soil build-up on the double-shoot paired row and side band openers, which in turn reduces soil throw and disturbance.

Air Hose Grommets

Grommets prevent straw and debris from falling into the top of the seed and fertilizer ports on the openers. This option is available for the double shoot paired row and side band openers with regular outlet distribution hose.

clearance

Moves residue up and off the shank faster, letting you seed in challenging conditions.

Single Shank

The C2 Contour’s single shank design offers better residue clearance and lower draft requirements and better fuel savings.

Reclined Shank Angle

At the heart of the C2 Contour’s improved ability to shed residue is the design of the shank. The reclined 12-degree shank angle moves residue up and off the shank faster. The shank has the same angle as the edge-on shank on Morris hoe drills.

Opener Clearance

The distance from the ground level to the catch point has been increased by 60 percent to 21 inches on the C2 Contour. When residue flows off the shank instead of building up, the potential for bunching is significantly reduced.

C2 v.s. Contour Shank

precision

Place seed and fertilizer accurately for faster, more even germination.

Parallel Linkage

Features true “one-to-one” parallel linkage. It maintains a constant opener angle relative to the soil and a constant opener depth relative to the packer wheel throughout its 17-inch range of travel. The opener can contour up 10 inches and down 7 inches. Optimized opener-to-packer distance allows for excellent soil flow around the openers and back into the furrow while maintaining excellent depth control accuracy.

Depth Setting

The C2 Contour opener cam is higher and away from the ground so opener adjustments are much easier to make. The notched cam-and-pin system is at ¼ inch intervals. Rotate the cam by hand and insert the pin to lock in the desired seeding depth. Fine tune your seeding depth without tools or heavy lifting. Openers in wheel tracks can be set deeper when needed to compensate for compacted soil.

Row Spacing

Opener spacing options are 10-inch or 12-inch on drill sizes up to 71 feet and 12-inch on sizes over 80 feet.

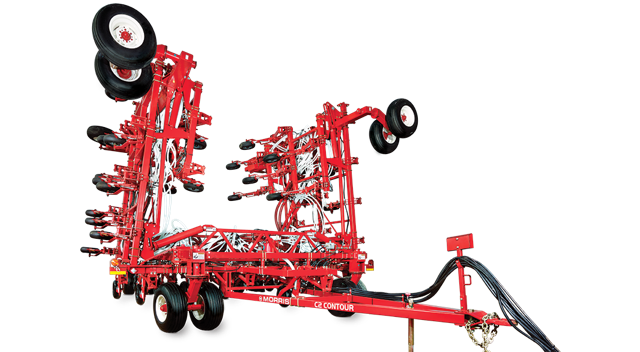

3 & 5 Frame Configurations

The C2 Contour is available in a heavy-duty three frame configuration from 41 feet to 51 feet and a five frame from 61 feet to 90 feet.

Narrow Transport Models

Narrow transport models in 25 feet and 31 feet widths are also available for smaller acre farms.

technology

Smart engineering for many years of dependable performance.

Hydraulic Cylinders

A double-acting hydraulic cylinder raises and lowers the opener from working to transport position. Pressure is maintained on the opener cylinders through a passive hydraulic system that uses a unique hydraulic accumulator system. Double wear rings in the opener cylinder along with premium hydraulic seals ensure long term field performance.

Hydraulic Accumulator

Acts a hydraulic cushion for the trips. Trip out force can be adjusted from 300lb to 700 lb at 1200psi, and packing force increases proportionally from 80 lb to a maximum of 200 lb. Once set, pressure may be adjusted from the tractor cab. A convenient, easy-to-read digital display is provided in the cab. This passive system requires lower hydraulic flow (saving up to 8 gal/min) and greatly reduces demand on tractor hydraulics, compared to the continuous flow required by similar drills. Opener pressure may be adjusted on the go from the tractor cab using a single hydraulic remote.

Valve Block

A hydraulic valve manifold providing all operator adjustments is conveniently located on the front bar of the drill. A manifold valve outfitted with high-flow components reduces opener cycle times by locking accumulator pressure in the hydraulic circuit during opener cycling, to avoid recharging the system each time openers are lifted and lowered.

packer wheel

Opener design that gives you options when changing seeding requirements.

Heavy-duty Packer Wheels

Packer wheels feature 1000-lb rated greaseable hubs, with twine guard and triple-lip seal bearings. Packer wheel choices:

- 5.50" x 16" semi-pneumatic

- 4.80" x 16" pneumatic

- 4.80" x 16" semi-pneumatic

- 4.50" x 16" semi-pneumatic Otico

- 5.50" x 16" semi-pneumatic Otico

- 4.00" x 16" ‘V’ crown

Brochure

Brochure