Take your operation to the next level

Farmers who own Morris Equipment tell us they grow better crops and appreciate our established reputation for accuracy and reliability.

Farmers’ #1 challenge today is getting their crop planted on time. They are achieving this with larger machines and more hours in the field. Our customers have told us: stay the course on precision and reliability and shift your design focus to making our equipment easier to use and building it to last. The Quantum drill is chock full of ideas to make those long hours more productive with automated features like our ICT sectional control system, headland management and packing force control. The all-new frame built with the Duraloc™ welding joint, heavy duty cast row units and the extensive use of stainless steel demonstrate our commitment to building equipment that passes the test of time.

Confidence

Quantum drill owners love how rapidly and uniformly their crops emerge. Getting all the little details right is key to designing a high performance one-pass air drill. Our customers have praised the Quantum drill’s unwavering accuracy, knowing that every seed is planted at the right depth. However, there is more to this story than just depth control. Morris double shoot openers place seed and fertilizer to optimize seed safety while providing early nutrient availability so crop emergence is strong regardless of the challenges Mother Nature sends our way. Soil to seed contact is the last key aspect to drive rapid uniform emergence and opener design, packer choice and trash flow all have an important role. Confidence comes from knowing your equipment will perform flawlessly in all field conditions, helping you grow your best crops.

Our Customers tell us they grow better crops with

Morris Equipment

Why settle for a good crop when you can grow a great crop?

In this demonstration in Falher, AB, the Morris canola population was 7 plants/ft² and was a full leaf stage more advanced versus the farmer’s independent opener machine at 5 plants/ft². Rapid uniform emergence and low seedling mortality is why Morris Quantum owners know they grow better crops.

Accurate Depth Control

The Quantum Air Drill precisely places seeds at the correct depth, ensuring optimal germination and growth. The Quantum Air Drill is designed to adapt to varying field conditions with a 1:1 contour ratio, following the natural undulations of the terrain for consistent planting. This superior design guarantees that every seed is uniformly covered, reducing the variability that can affect crop performance.

Outstanding Fertilizer-Seed Separation

One of the standout features of the Quantum Air Drill is its Double Shoot Opener, which incorporates a patented design that sets it apart from the competition. This innovative system ensures that fertilizer is dropped into a channel cut by the opening knife, where it remains securely in place. The precise placement of fertilizer optimizes nutrient absorption, leading to healthier and more robust crops. This advanced technology not only maximizes crop yield but also minimizes waste, making it an environmentally friendly choice for modern agriculture.

How much fertilizer can I safely apply in the band?

We use a crop injury threshold to provide our customers with advice on safe fertilizer rates.

This threshold is set at 85% of the unfertilized crop emergence. Any fertilized crop with emergence at or above the crop injury threshold is acceptable. The small plot replicated canola summary shows that all fertilizer rates tested are above the red line and safe.

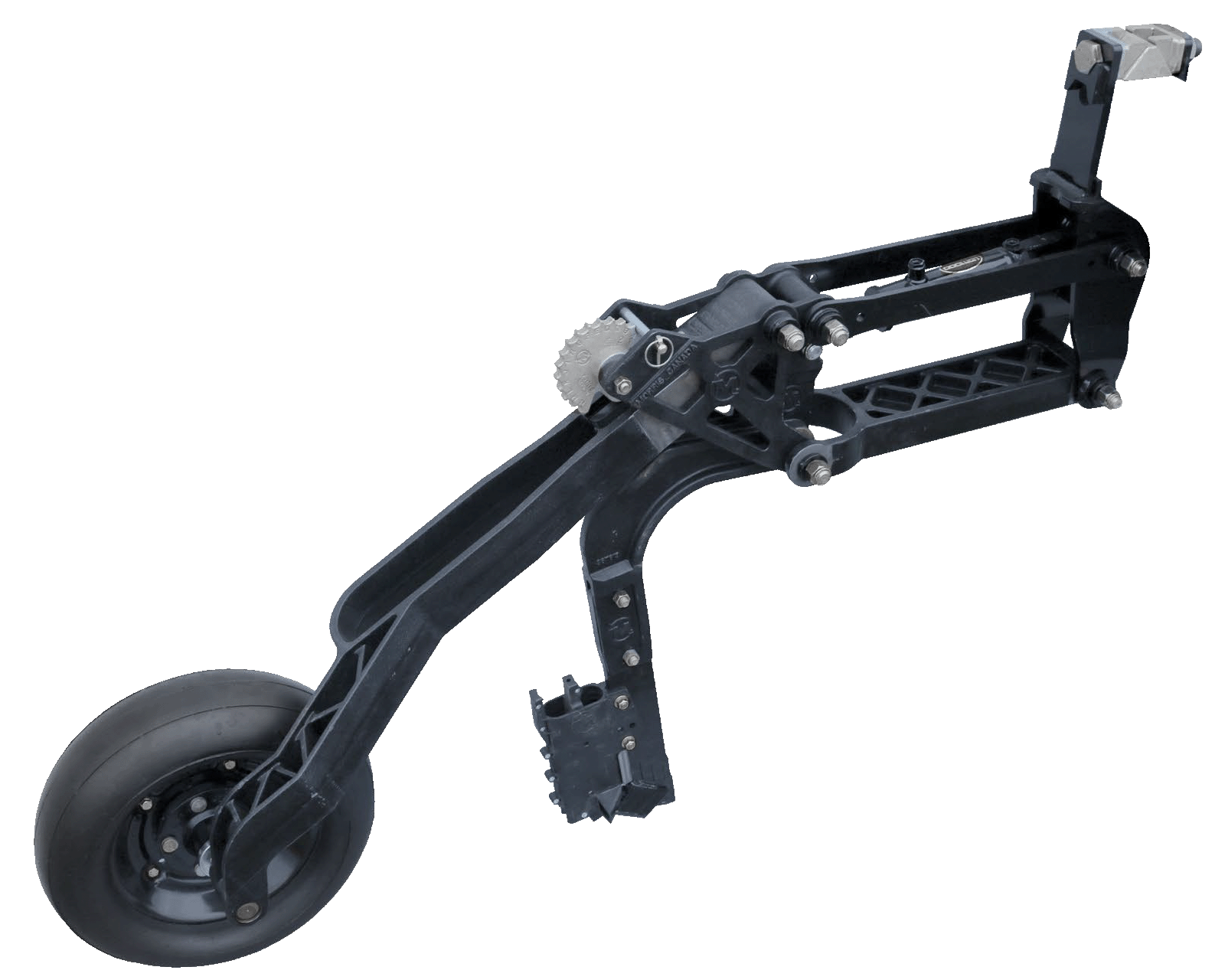

Soil Seed Contact

To promote uniform seed germination, we pack the soil around the seed. Packing breaks down large soil aggregates and reduces soil porosity, which allows water to move from higher soil moisture areas to the packed soil surrounding the seed.

Morris has been deliberate in our design efforts to optimize soil-seed contact and seed germination. Our double shoot openers are designed to minimize soil fracturing and maximize soil flow around the boot and into the furrow prior to packing. The packer tire then applies downforce that is distributed across an optimized surface area.

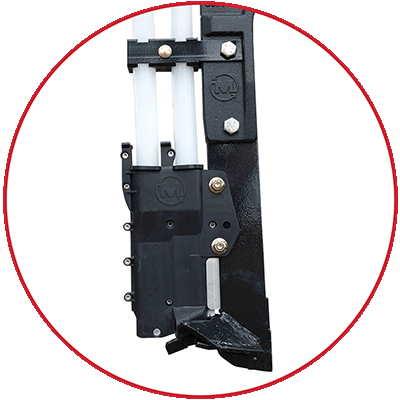

Single Shoot Opener

Double Shoot Opener

Key design elements Morris double shoot openers employ to minimize soil disturbance:

- The ½" wide nose opens the soil and cuts rather than fractures soil.

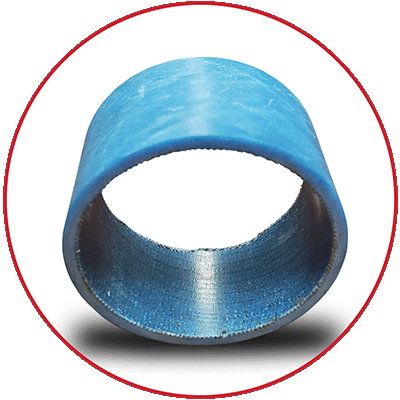

- The narrow injected polymer boot.

- Carbide covers the shovel surface to improve wear life and minimize soil disturbance.

Control

The Quantum air drill is chock full of user-friendly features to operate the drill at peak performance. Make steady uninterrupted progress with large floatation tires that keep the machine from getting bogged down in wet spots and the industry leading trash clearance provided by Quantum row unit design that minimizes catch points and promotes flow of crop residue as well as the optional 4th row kit for the Quantum frame. Technology is at its best when it makes your life easier and improves machine performance. Headland management automatically lifts and lowers the Quantum row units on headlands and packing force control adapts to changes in soil hardness across your fields to ensure your furrows are consistent and seed placement is perfect. Morris sectional control on 9 and 10 Series air carts turns product off and on so that there are no expensive overlaps or embarrassing misses in your fields. With Morris Equipment, you have the power to control your farming destiny.

Top notch flotation

The large 600/50-22.5 tires and the low pull point of the Quantum drill mean more time seeding and less time bogged down in wet spots.

Class Leading Trash Clearance

The Quantum Air Drill from Morris Equipment features class-leading trash clearance, allowing for efficient residue management. This capability ensures that the drill can operate smoothly even in fields with heavy crop residue, minimizing blockages and downtime. The superior trash clearance system is designed to handle the demands of modern farming, maintaining consistent performance across various field conditions and crop types.

Row Spacing Choice

Farmers can customize their planting configurations with the Quantum Air Drill's flexible row spacing options. Whether you prefer narrow or wide row spacing, the drill can be adjusted to meet your specific requirements, optimizing seed placement for different crops and maximizing yield potential. This adaptability is a testament to Morris Equipment's commitment to providing versatile and user-friendly solutions for precision agriculture.

Productivity Boosting Features

The Topcon controls used on the Quantum drill are second to none.

- Pressure Control – From the convenience of your tractor, you can increase or decrease operating pressure to optimize the Quantum drill’s performance in different soil conditions. The drill is lifted and lowered on headlands without touching the hydraulic remote.

- Input Control Technology (ICT) – The ICT sectional control system Morris developed and perfected on our 9 Series air carts is controlled by TopCon resulting in a fully automated system that prevents over-application of seed and fertilizer by shutting off sections that are typically 7-8' widths.

- Headland Management – This optional feature automatically lifts and lowers the drill as it enters or exits headlands. This is a great convenience feature that minimizes seed and fertilizer over-application.

- Packing Force Control – This feature maintains consistent packing force and optimizes opener penetration across variable soil conditions by managing opener hydraulic pressure on Quantum drills equipped with this feature.

- JEM Pressure Control – The JEM controller is used for pressure control with Morris mechanical drive carts and non-Morris air carts. The controller will increase and decrease pressure in 25 psi increments as well as lift and lower the drill while the tractor hydraulic remote is engaged.

Quality

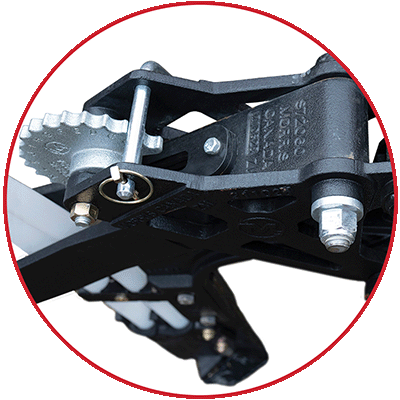

The Quantum air drill is designed to be a long-term investment for our customers. The frame is held together by the patented Duraloc™ welding joint, an innovation that is 154% stronger than traditional butt-welded frames re-enforced with gussets. The Quantum row units are the heaviest in the market. When turning around tight rock piles or other obstructions, you won’t bend these row units or break the mounting hardware that attach them to the frame. Quality materials matter. Quantum drills are covered with UV resistant powder coat paint and utilize stainless steel extensively for product delivery to the soil. We want your machine to pass the test of time and look great doing it.

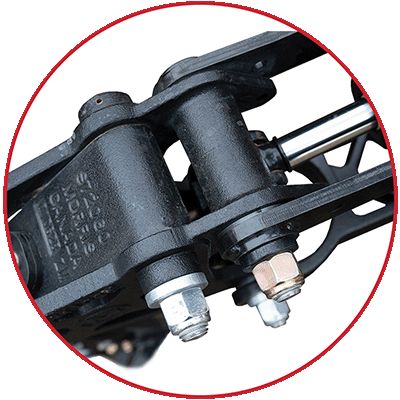

Re-inventing the air drill

Air drill frames have traditionally been fastened with butt joints and reinforced with gusseting to reduce frame cracking. Morris invested in a tube laser and this allowed us to develop and patent a new stronger welding joint to build frames. The Duraloc™ welding joint possesses 154% greater breakaway strength according to third party testing.

Durability

From the front hitch to the back, and every millimetre in between, the all-new Quantum is completely redesigned from the ground up for exceptional strength, durability, and longevity.

Strong Hitch

Engineered tough, without compromise! Placing the centre row unit at the rear of the drill is one of the new ideas Morris has used to make this heavy duty hitch.

Big Primaries, Big Capacity.

The primary lines on the Quantum drill have been increased to 3" diameter to accommodate the increased fertilizer rates farmers use today to maximize yields. Stainless pipe is used in straight sections and urethane-lined flexible hose in curves and wing-folds. Primary lines are plumbed outside the frames to eliminate the possibility of catching and kinking during folding into transport.

Flat fan divider heads

The flat fan divider head is another Morris innovation that allows seed and fertilizer to travel in a smooth lateral flow from the air cart to the drill which increase air system capacity. This unique design has an established reputation for being gentle on the seed and allowing for very high product application rates. Our new stainless steel heads have a 30% larger internal area to improve passage of large seed and maintain a consistent level of variation to each opener at product application rates up to 450 lb./acre.